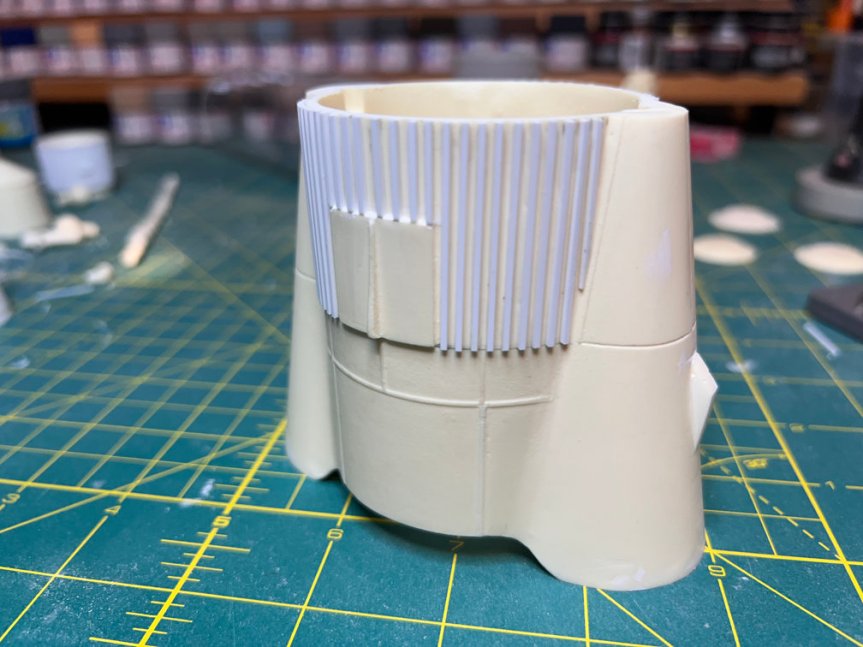

While studying the model and what I had done with the stringers on the capsule adapter, I decided that I had to fix the stringers on the boat tail. I sanded down the molded in stringers on one side of the part. I was able to sand down all the raised parts without much trouble. Also note on the lower part of the boat tail I sanded down some molded in strips that were much too tall. I sanded them to match the other raised parts on the lower boat tail.

Sanding them off did not reveal any new pin holes. Yea!! I also made similar changes to the opposite side.

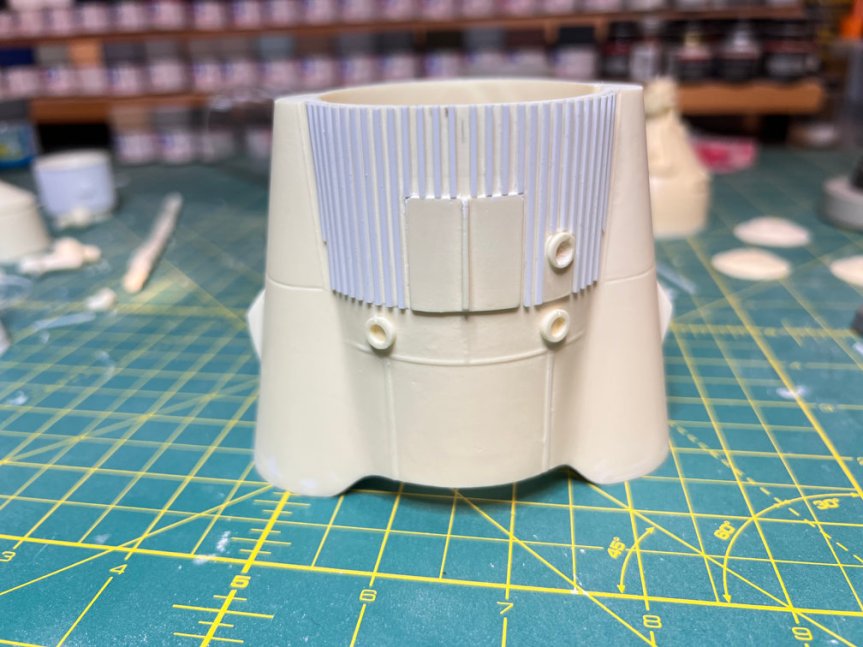

The stringers are 2″ square on the full size vehicle. That makes 0.040″ square strips just about right at 1/48 scale. I had more than enough on hand so no trip to the hobby shop was needed. Here is a photo of the side where the fill and drain lines are. All the stringers have been installed on this side.

To make my guide marks I put the part upside down on the drawing and marked where each stringer should be for both sides. Minor adjustments had to be made to fit all the stringers around the details.

I used a similar procedure to put the stringers on the other side.

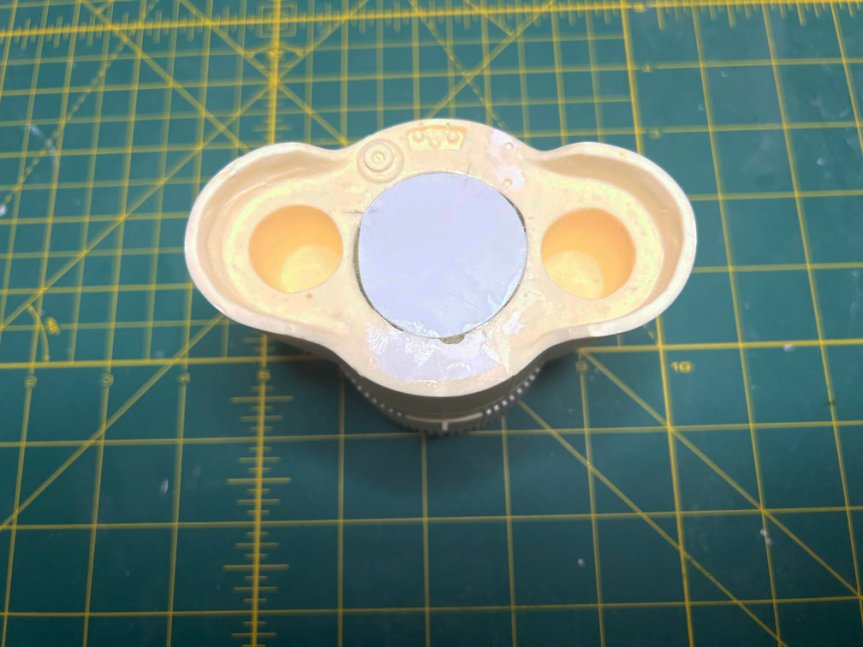

I then started on the under side of the boat tail where the nozzles will be. There is a much too large hole for the center nozzle to pass through. I made an approximate pattern for the hole and then cut a disk of 0.040″ sheet stock. I made a few adjustments to get the disk to fit the hole and then used some Plasti-zap CA glue to hold it in place. Blue painters tape was applied over the disk on the outside to keep any epoxy from seeping out of the edges. I then mixed up some 5 minute epoxy and applied it to the edges of the disk on the inside of the hole. Here is a photo after the blue tape was removed.

I placed the center engine heat shield where it will eventually be placed to show how much larger the hole was compared to the heat shield.

For grins I placed the other two heat shields and took a photo. The heat shield with the hole is the one I’ll open up first so the nozzle can be placed through it.

That’s it for this update. I hope to get all the heat shields opened up and start test fitting the nozzles soon.

Thanks for looking. See below to subscribe.