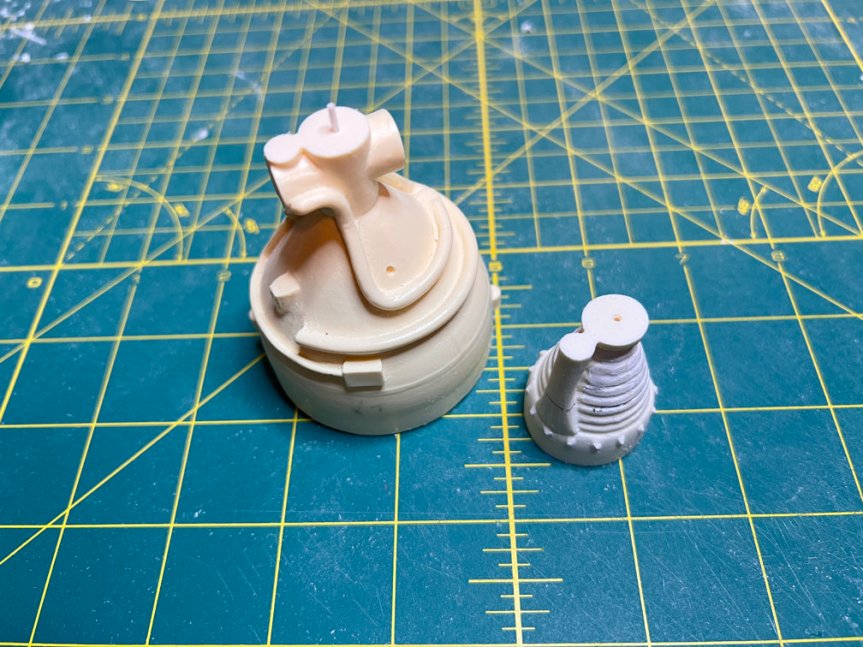

To get ready to open the center heat shield I did a rough measurement and then used a grinding bit to open the shape. In the photo above, the protrusion on the left is for the turbopump exhaust that is on the center nozzle.

I opened up the heat shields. I started by drilling a small hole near the center. Then I used successively larger bits up to 11/32″. Then I used a small sanding drum in my Dremel to widen the hole. Then it took many test fits to get the hole to the proper size to fit the nozzles. The center heat shield with the protrusion was carved out with a small straight grinding bit. They are quite thin and I held them by hand while grinding out the excess resin.

I drilled a 1/16″ hole in both the sustainer base and the nozzle. I put a 1/16″ rod in the base end and it will be used as a locator pin for the center nozzle.

During the heat shield process I was test fitting all the nozzles.

Once all the heat shield were ground to the proper size I test fitted everything.

They look pretty good. Now time to make the main turbopump exhaust pipe. Hopefully I can get some more work done this next week. So many things and so little time.

Thanks for looking. More to come soon.